PVC heat-resistant modifier

As a heat resistant modifier for PVC, PMMA resin, and photosensitive materials, it can not only improve the heat resistance temperature of the resin, but also some mechanical properties (such as hardness, tensile strength, etc.), hot melt and processing properties.

Content Introduction

/ introduce

RANGE SUMMARY

· Product name: PVC heat resistant modifier

· Abbreviation: NSA copolymer

· Physical and chemical properties: The copolymer appears as white or slight yellow powder. insoluble in water, toluene and xylene,however, it can be soluble in organic solvents such as tetrahydrofuran, N, N-dimethylformamide, etc.

· Molecular structure: Random amorphous copolymer.

PVC heat resistant modifier is obtained by emulsion polymerization of N-phenylmaleimide monomer and other monomers. The copolymer has a uniform glass transition temperature and excellent heat resistance stability, and has good compatibility with PVC and other resins. It is a very effective and economical heat resistant modifier for PVC and other resins. It can not only significantly improve the temperature resistance of PVC resin, but also improve its processing performance and Hardness, which has effective modification effects for PVC resin

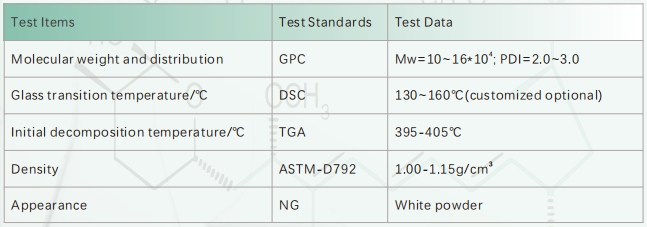

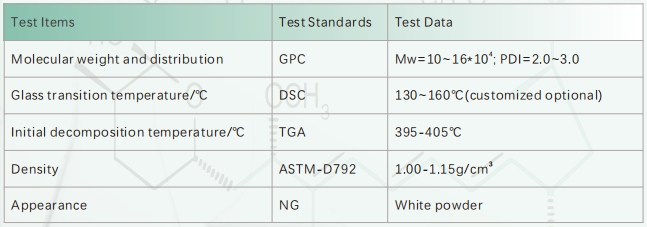

TECHNICAL SPECIFICATIONS

APPLICATIONS

As a heat resistant modifier for PVC, PMMA resin, and photosensitive materials, it can not only improve the heat resistance temperature of the resin, but also some mechanical properties (such as hardness, tensile strength, etc.), hot melt and processing properties. According to the different content of N� phenylmaleimide in the copolymer, the copolymer has different glass transition temperatures. When the dosage of NSA in PVC/NSA composite material is 10-30wt.%, the heat resistance temperature of polyvinyl chloride can be increased by 15-45 ℃.

微信号:wexinhao

微信号:wexinhao

首页

首页

添加微信

添加微信

电话咨询

电话咨询